What is Virtual Prototyping?

In this fast-paced world, businesses are always seeking to innovate faster, reduce costs, and bring better products to life. That is where virtual prototyping comes in - a game-changing approach using digital tools for creating, testing, and perfecting product designs before they are ever brought to the physical world. Companies can identify flaws, optimize performance, and accelerate time-to-market in ways that never existed before.

How Virtual Prototyping Works

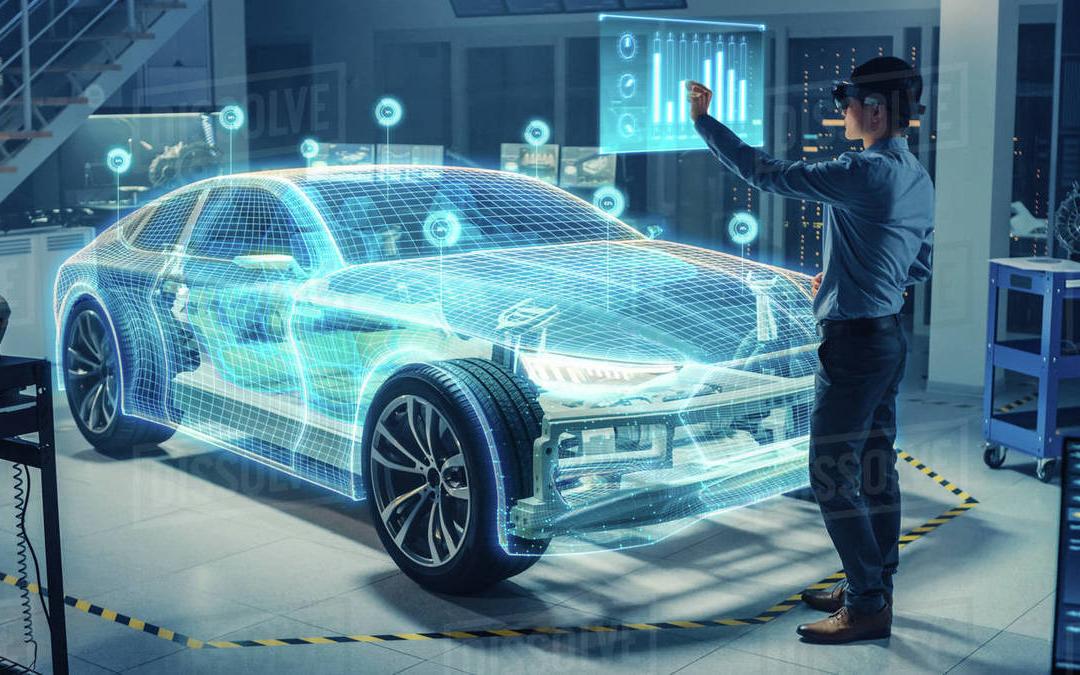

Virtual prototyping is used to create a virtual model or replica of the product using advanced software tools. Here, 3D models can be tested in different conditions so that designers and engineers can eventually evaluate all the functionality, aesthetics, and usability without creating any physical prototype.

Such an approach is incredibly critical in industries like automotive, aerospace, healthcare, and consumer electronics, where traditional prototyping would be both time and cost intensive. More importantly, with 3D virtual prototyping, teams can iterate rapidly, collaborate seamlessly, and bring ideas to life with unprecedented precision.

Role of AR and VR in Prototyping

While virtual prototyping primarily relies on 3D modeling software in its applications, incorporating AR (Augmented Reality) and VR (Virtual Reality) virtual prototyping to the mix makes a whole world of a difference. Here's how it works:

Virtual Prototyping through AR

Integrating into the Real-World: AR enables superimposition of digital prototypes onto physical spaces so that one can view whether the product really fits in any real-world conditions. For example, automobile engineers can project an image of a virtual car dashboard onto the actual automobile's frame.

Collaboration and Coworking: Teams can share and review prototypes in real-time using AR even when they're miles apart.

VR Virtual Prototyping

Immersive Testing: While using VR, teams are creating fully immersive environments where the designers can touch and feel the prototypes as if they were actual products. The same is highly applicable for user experience testing for consumer electronics and furniture.

Validation of Design: Engineers can build a risk-free virtual space with simulations for stress tests, ergonomic evaluations, and even user interactions.

Together, AR & VR prototyping bridges the gap between imagination and real life, offering fast innovation while enabling more effective and precise decision making.

Advantages of 3D Virtual Prototyping

Why are companies across industries embracing 3D virtual prototyping? Here are the key advantages:

Cost Savings: Eliminates the need for multiple physical prototypes, reducing material and labor costs.

Faster Iteration: Design changes can be made and tested in minutes, not weeks.

Improved Collaboration: Teams worldwide can access and review the same digital prototype in real time.

Risk Reduction: Identifies design flaws early, preventing costly mistakes during production.

Sustainability: Reduces waste by minimizing the use of physical materials.

Applications of Virtual Prototyping Across Industries

Virtual prototyping is changing the way industries approach product development. Here's how it does it:

Automotive and Aerospace: Car manufacturers like Tesla and Ford use 3D virtual prototyping to design and test vehicle components, from engines to interiors. Aerospace companies simulate flight conditions to optimize aircraft performance and safety.

Healthcare and Medical Devices: Surgeons use virtual models to plan complex procedures, while medical device companies prototype implants and instruments with pinpoint accuracy.

Consumer Electronics: Companies such as Apple and Samsung use AR VR prototyping to test the ergonomics and functionality of smartphones, wearables, and other gadgets.

Architecture and Construction: Architects make virtual building models to visualize designs, test structural integrity, and present ideas to clients.

Comparison: Virtual Prototyping Tools and Platforms

Here’s a quick comparison of popular tools for virtual prototyping, AR VR prototyping, and 3D virtual prototyping

The Future of Virtual Prototyping

Virtual prototyping is becoming more accessible and powerful with the evolution of technology. Some emerging trends include:

AI-Driven Design: AI algorithms can generate and optimize prototypes based on specific requirements.

Cloud Collaboration: Teams can work on the same prototype simultaneously, regardless of location.

Haptic Feedback: Adding touch sensitivity to AR/VR prototypes for a more realistic experience.

By 2030, the global virtual prototyping market is projected to reach $10.5 billion (Source), driven by demand for faster, smarter, and more sustainable product development.

Why Your Business Needs Virtual Prototyping

Whether you’re designing a cutting-edge gadget, a life-saving medical device, or a sleek new car, virtual prototyping can help you:

Save time and money.

Improve product quality.

Stay ahead of the competition.